COF (Chip-On-Film) Technology for LCD Driver

Basically, a COF bonding can manage or supervise the operation of bonding machines, which employ adhesives to unite things in preparation for additional processing or to make a finished product. For example, glueing veneer sheets into plywood, glueing paper, or combining rubber and rubberized fabric pieces, plastic, simulated leather, or other materials are all examples of jointing processes.

Centers that give various categories of training and learning, such as software, hardware, web development and networking, may be found almost wherever you look. In addition to this one may learn about the fundamentals of security, maintenance, and troubleshooting processes, among other things. In order to make an informed decision when choosing a center, you must understand the possibilities and how it might help you in the long term. The high dependability comprises aging and peeled tests that were conducted to evaluate the product experience of the COF and NCA process in conjunction with one another.

If you are a newcomer in this field, the first criterion you must consider is finding reputable COF bonding training despite the fact that you will come across numerous centers you must finalize and pick the most appropriate one based on factors such as location, class size, training facilities, accreditation and its courses, as well as fees and other costs. There are also certain facilities that provide special discounts on specific programs, which might be a very attractive incentive to enroll in one of them.

Why COF bonding is important?

In the chemical world, an adhesive is a substance that has the capacity to bond two or more materials together. The ability of adhesives to perform this job is related to their ability to form a surface connection that is difficult to separation. When the adhesive molecules adsorption onto a solid surface and due to its reaction with it, a connection is formed between the two surfaces. Adhesives are very important in almost every industry, both for structurally and non-structural applications. COF provides a general concept of the options for sticking materials together by bonding. COF bonding training have years of expertise in this field, which allows providing the most comprehensive range of LED/LCD Tab Bonding Machine Repairing Services available anywhere. These are completed in accordance with the specifications of the client. The low pricing, flawless mending, and client-focused approach of the offered welding machine repairing services have earned them widespread recognition.

The Training Courses are designed to educate individuals with an in-depth and comprehensive understanding of chip, glueing process and their components, as well as the complicated science behind their functioning, connection, and networking. Through the training, you will get an understanding of the variable roles that each component and piece of technology performs in the overall operation of the system.

This is most likely due to a combination of factors such as decreasing costs, increased demand for lightweight constructions, the development of more lasting adhesives, and enhanced structural adhesive effectiveness. Furthermore, adhesives are often more effective in transferring load than welded constructions.

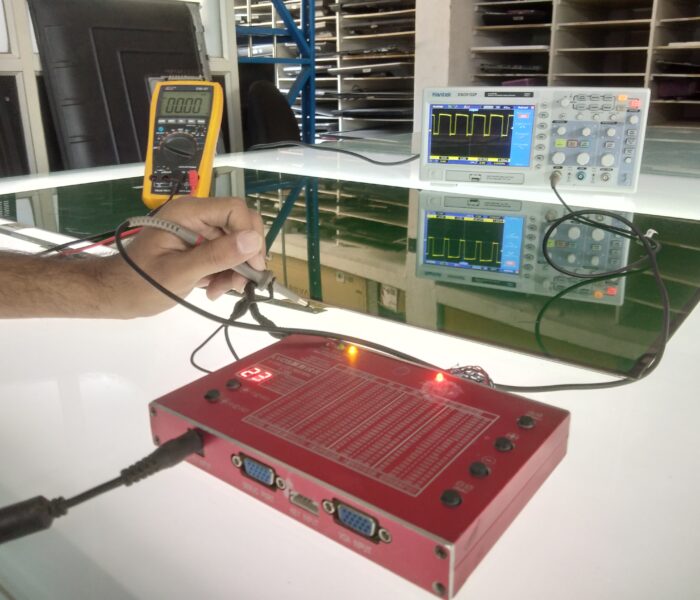

Automatic COF bonding machines that have been built just for you are implemented according to your requirements. Its manual solo or multiple workstations are available in both manual and completely automation configurations for tab, LCD production. It takes varying amounts of time to heat up depending on how dense the current flow is.

Also Read: What Do You Know About The Motherboard Chipset?

Compared to the traditional tape-automated-bonding (TAB) and chip-on-glass (COG) methods of connectivity of liquid crystal modules, the COF method is more cost-effective (LCM). The film’s thickness, which is more flexible than TAB, may be as thin as 44, making it ideal for use in medical applications. It has the capacity to do pre-tests, while COG does not. It has significant promise in a wide range of product fabrication applications.

Bottom Line

As of this writing, the current COF technology not only allows for the mounting and loading of a wide range of peripheral components, but it also allows for the loading of a large number of individual chips (multi-chip technology) onto the tape. It is commonly expected that this technology would become more important in the future for simplifying the systematization of devices such as mobile phones and personal digital assistants (PDAs).