Category: Technology

COF (Chip-On-Film) Technology for LCD Driver

Basically, a COF bonding can manage or supervise the operation of bonding machines, which employ adhesives to unite things in preparation for additional processing or to make a finished product. For example, glueing veneer sheets into plywood, glueing paper, or combining rubber and rubberized fabric pieces, plastic, simulated leather, or other materials are all examples of jointing processes.

Centers that give various categories of training and learning, such as software, hardware, web development and networking, may be found almost wherever you look. In addition to this one may learn about the fundamentals of security, maintenance, and troubleshooting processes, among other things. In order to make an informed decision when choosing a center, you must understand the possibilities and how it might help you in the long term. The high dependability comprises aging and peeled tests that were conducted to evaluate the product experience of the COF and NCA process in conjunction with one another.

If you are a newcomer in this field, the first criterion you must consider is finding reputable COF bonding training despite the fact that you will come across numerous centers you must finalize and pick the most appropriate one based on factors such as location, class size, training facilities, accreditation and its courses, as well as fees and other costs. There are also certain facilities that provide special discounts on specific programs, which might be a very attractive incentive to enroll in one of them.

Why COF bonding is important?

In the chemical world, an adhesive is a substance that has the capacity to bond two or more materials together. The ability of adhesives to perform this job is related to their ability to form a surface connection that is difficult to separation. When the adhesive molecules adsorption onto a solid surface and due to its reaction with it, a connection is formed between the two surfaces. Adhesives are very important in almost every industry, both for structurally and non-structural applications. COF provides a general concept of the options for sticking materials together by bonding. COF bonding training have years of expertise in this field, which allows providing the most comprehensive range of LED/LCD Tab Bonding Machine Repairing Services available anywhere. These are completed in accordance with the specifications of the client. The low pricing, flawless mending, and client-focused approach of the offered welding machine repairing services have earned them widespread recognition.

The Training Courses are designed to educate individuals with an in-depth and comprehensive understanding of chip, glueing process and their components, as well as the complicated science behind their functioning, connection, and networking. Through the training, you will get an understanding of the variable roles that each component and piece of technology performs in the overall operation of the system.

This is most likely due to a combination of factors such as decreasing costs, increased demand for lightweight constructions, the development of more lasting adhesives, and enhanced structural adhesive effectiveness. Furthermore, adhesives are often more effective in transferring load than welded constructions.

Automatic COF bonding machines that have been built just for you are implemented according to your requirements. Its manual solo or multiple workstations are available in both manual and completely automation configurations for tab, LCD production. It takes varying amounts of time to heat up depending on how dense the current flow is.

Also Read: What Do You Know About The Motherboard Chipset?

Compared to the traditional tape-automated-bonding (TAB) and chip-on-glass (COG) methods of connectivity of liquid crystal modules, the COF method is more cost-effective (LCM). The film’s thickness, which is more flexible than TAB, may be as thin as 44, making it ideal for use in medical applications. It has the capacity to do pre-tests, while COG does not. It has significant promise in a wide range of product fabrication applications.

Bottom Line

As of this writing, the current COF technology not only allows for the mounting and loading of a wide range of peripheral components, but it also allows for the loading of a large number of individual chips (multi-chip technology) onto the tape. It is commonly expected that this technology would become more important in the future for simplifying the systematization of devices such as mobile phones and personal digital assistants (PDAs).

Know the Technology behind repairing LED and LCD panel

Significance of LED displays in display

When shopping for television these days, most people are searching for either an LED or an LCD model, depending on their budget. Who doesn’t want to know that the film, documentary, or video clip they’re viewing is visually appealing? In general, the greater the sound quality, the better the visual quality should be in tandem with each other. LED display technology is the most widely utilized kind of display technology in display systems. LED displays provide vivid colors as a result of the use of LED lights.

As energy supplies are depleted on a daily basis, this has become a critically essential problem. People who use extremely little energy, in particular those who deal with electricity, are in high demand. It does not only result in the purchase of the panels, but it also raises your expenditures when you use it on a constant basis, as well as your power bill.

Is it true that LED and LCD are the same things?

There are a great number of LEDs and LCDs available on the market, and each of these televisions has different features and their panels are also not the same. Its been thoroughly examined by industry professionals. However, since there are so many different led available, it is only natural for the customer to get completely puzzled. It is disheartening to learn that many of the purchasers are unaware of the differences between an LED and an LCD television set.

LCD monitors are used in all LED displays. However, not all LCD displays are made of LEDs. In the same way, as all eagles are birds, not all birds are eagles, and vice versa. While the titles may be complicated to those sifting through specifications in search of the finest monitor, once you break it down, it’s much simpler to comprehend than you would think.

The need for LED LCD panel repair training

Because of the rising economy and steady rise in spare money, the majority of people are purchasing the finest televisions available on the market, which are equipped with the most up-to-date technology. Because of the growth in demand and the need to stay ahead of the severe competition, television manufacturers study and produce television models that have the most up-to-date features for the benefit of customers. LED TV and LCD TV technologies are the most recent technologies to hit the market and are now accessible. Currently, these technologies have gained widespread popularity among the general public, thanks to their bright and spectacular colors, as well as their gorgeous acoustics and other benefits.

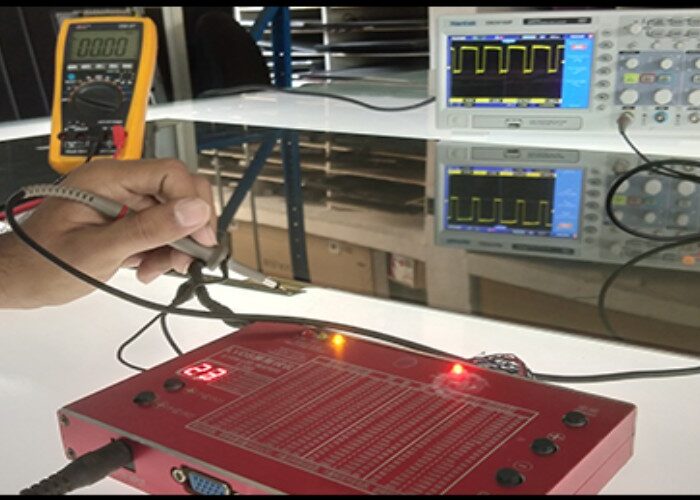

These days we should know that the need for LED LCD panel repair training courses is expanding at an alarming rate, and one of the primary reasons for this increase in demand is the inevitable growth in the sale of LED televisions. By taking an LED TV fixing course, one may either create their own company or, if that is not an option, make a good living in a position with a good wage package. There are many institutes that are best in offering LED LCD panel repair training for laptops, smartphones, LED LCD TVs, printers, and closed-circuit television systems. These institutes give full online assistance is provided to students via an LED LCD TV Repair Forum where learners may ask any questions, they may have without having to worry about being judged by their peers or feeling self-conscious. Course on fixing LCD, LED, and Smart TVs. They even offer an online led television repair course and learning materials, as well as a connection to the led television bios software.

Also Read: A Detail Guide on LED LCD Panel Repair for Advanced Technicians

The repair training centers are founded with the goal of producing highly skilled indigenous technological professionals to help emerging countries accelerate their economic development. They present students with a one-of-a-kind learning environment where they may discover self-improvement via on-the-job training It is important to note that the courses given by the institution are professional and skill-based in order to ensure that students can put their newfound knowledge into practice while on the job. Once you study LCD LEDs from a reputed LED LCD panel repair training institution there are chances where you will be confused as to what you have to do. But after learning ultimately you will be unable to remain jobless since the purpose of starting this course is to provide a fundamental medium for a large number of individuals to make a substantial amount of money.